Component Delivery

Intelligent Feeder Concept

The C5 is built around the intelligent feeder concept. Each feeder has a unique ID to which a part number or reel/tube ID can be “married to”. Now you can place the feeder anywhere on the machine because the feeder is constantly communicating with the machine.

Automatic Pocket Pitch

When a part is loaded onto a feeder, the machine automatically sends the correct feeder index command to that feeder.

Multi-Function Status Light

During normal operation the four color status light can warn the operator that the feeder has reached its programmed low quantity. During Job Setup the status light can indicate which feeders have part numbers on them that are used on the next job and which feeders don’t. |

|

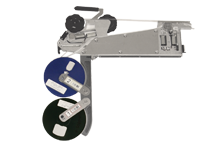

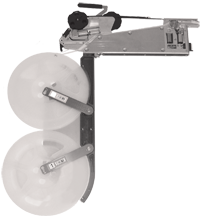

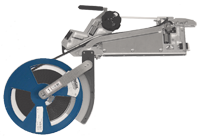

Electronic Tape Feeders

|

All of the ETF Series Tape Feeders are superbly constructed from precisely manufactured components, starting with the rugged one piece CNC milled feeder body. An ergonomic handle and integrated reel hanger facilitate one hand removal and replacement of the feeders - even as the machine is running.

The ETF8D dual lane 8mm feeder can feed any tape (i.e. embossed or punched) and all of the ETF Series Tape Feeders can index any pocket pitch. All ETF tape feeders come equipped with cover tape tethers that minimize cover tape leader length requirements. A four-color status light is used to indicate among other things “low quantity” or “maintenance due”. During machine setup the lights can indicate which feeders are “used” or “not used” on any given job.

A three point mounting system with a quick release pin ensures spot on feeder mounting every time. The feeders, while motor driven, provide repeatable and accurate pocket position by a supplemental mechanical means on every actuation.

Feeders are often considered the “razor blades” to placement machines. But the price of an individual feeder does not tell the whole story about overall feeder costs. Often overlooked is total number of feeders required. Some manufacturers require different feeders for different tapes styles and or pitches. Some even require different feeders depending on the component size in 8 mm tape. The versatility of the ETF Series Tape Feeders equates to reduced feeder inventory which reduces overall cost. For example, the Adjusti-Flex feeder significantly reduces the required number of the more costly larger tape feeders.

Any Tape - Any Pitch

The ETF8D dual lane 8 mm tape feeder can feed punched or embossed tape with 2 mm or 4 mm pocket pitch. |

|

Adjustable Width Feeders

|

The adjustable feeder can significantly reduce your feeder inventory on the larger more costly feeders. |

Tape Strip Feeding

The most effective way to deal with tape strips is to feed them as you would a normal tape without “special” feeders or additional programming. Tape strips can be prepared offline by splicing a small piece of scrap carrier tape as a trailer and applying the self adhesive cover tape extender. The tape strip can then be fed on a regular tape feeder with no component loss. |

|

Air Track Feeders

|

Tube feeders are often overlooked when evaluating placement machines. Vibratory type feeders are slow and unreliable and are typically accepted as a “necessary evil”. But non-reliable feeding of tube components can significantly degrade the performance of an entire SMT line.

Tube feeders should not require any special handling requirements but most do. During mounting / removal, transportation and storage vibratory or belt feeders are prone to damage or component spillage. All of the air feeder track assemblies are equipped with a shutter that keeps components in their place. The shutter closes automatically when the air track is released from the base or when the air feeder is removed from the machine.

Fast and reliable feeding is important once the tube feeder is on the machine. But efficient component replenishment andexchange plays an equally important role in overall productivity. Most tube feeders typically need to be removed from the machine during component replenishment.

Or, as an option, additional air tracks can be preloaded and quickly exchanged on the air feeder base without interrupting production.

Changing from one component to the next during job changeover can be cumbersome with conventional feeders. Very often there is a “reservoir” of components already out of the tube which then need to be put back into the tube typically with a vacuum pen or tweezers. Air tracks come with tube adapters that enable you to simply pour the remaining components back into the original tube and then pour the new component in.

Detachable Tracks

Air Tracks are available for all standard SMT components normally supplied in tubes.

Custom air tracks are available upon request.

EAFB - Electronic Air Track Feeder Base |

Detachable Tracks |

Easy Load-Unload

|

Air tracks come with tube adapters that enable you to simply pour the remaining components back into the original tube and then pour the new component in. |

Interchangeable Tracks

Components can be preloaded or stored in the Air Tracks for faster job set up. The Electronic Air Feeder Base accepts all track assemblies. |

|

Reload “On-the-Fly”

|

With the included tube adaptor an entire tube can be blown into the track enabling non-stop production. |

Standard Air Tracks

Model |

Lanes |

SO8-16 |

4 |

SOL16-40 |

3 |

SOT223 |

4 |

PLCC20 |

3 |

PLCC20-SOC |

2 |

PLCC28-32 |

2 |

PLCC28,32-SOC |

1 |

PLCC44 |

1 |

| PLCC44-SOC |

1 |

| PLCC52 |

1 |

| PLCC52-SOC |

1 |

| PLCC68 |

1 |

| PLCC68-SOC |

1 |

| PLCC84 |

1 |

| PLCC84-SOC |

1 |

| SOJ16-32-300 |

3 |

| SOJ14-42-400 |

2 |

| SOM8-24 |

4 |

| SOW24-36 |

2 |

| SOY28-44 |

2 |

| DPAK |

3 |

| D2PAK |

2 |

| TSSOP8-56 |

4 |

Slot Usage for Tape and Air Track Feeders

Feeder Model |

Slots |

ETF8D dual lane |

1 |

ETF12SS |

1 |

ETF12-32 |

2 |

ETF12-44 |

3 |

ETF12-56 |

4 |

EAFB with track |

2 |

Tray Handling Options

All of the tray handling options are designed to hold standard JEDEC trays.The tray handling software allows for custom trays including multi-array trays (several parts within one tray area with unique row and column spacing for each part array). All of the tray handling options on the C5 series have no impact on feeder capacity, board size or footprint and parts are picked directly from the trays.

STMR Single Tray Module Retractable

|

The STMR is a retractable single tray holder. One can be added to any single beam model to economically increase tray capacity when a TM15 is not present. On a dual beam machine up to two STMR’s can be added. |

TM6 Tray Module with 6 Trays

|

The TM6 is available on the C5-128 machine and replaces the stationary three tray holder. The simple side to side motion cost effectively expands the tray capacity from four to seven. |

TM15 Tray Module with 15 Trays

|

The TM15 is a 15 tray capacity random access elevator system that is installed within the footprint of the machine. One can be installed on a single beam machine or up to two on a dual beam machine. |

Through-Hole Machines

Through-Hole Machines